Description: This is a brand new book being sold by the author. The Browning 1885 High Wall BPCR models are the focus of the 1st section, but due to the relatively minor differences in the design, much of the material in the appendices is applicable to the full line of Model 1885 Rifles manufactured by Miroku for both Browning and Winchester. In fact, if you ever decide to disassemble your Miroku manufactured Browning or Winchester Model 1885 rifle, Appendix 1 alone may be worth the price of the book. The term "Miroku manufactured" is used here to distinguish modern Browning and Winchester Model 1885 rifles from 19th century and early 20th century "original" Winchester rifles. Published by TexasMac Publishing, the 13-digit International Standard Book Number (ISBN) is 978-0-9893702-5-7. The 10-digit ISBN is 0-9893702-5-7. The Library of Congress Control Number is 2013955482. The book is approximately 9" by 6", contains 418 pages of text, 7 tables and 95 figures. Only high-quality components and construction was used in the manufacturing. For those of you somewhat familiar with book binding, it has a hard case bound cover. The cover artwork is laminated to the cover under a layer of durable textured clear poly. The inside pages are cut from 60 lb. bright-white acid-free archival paper. The book block (inside pages) are bound with a mill and notch binding operation including the white 100% cotton end sheets. TABLE OF CONTENTS3RD EDITION COMMENTSPREFACESPECIAL ACKNOWLEDGEMENTSWARNING1. INTRODUCTION2. BACKGROUND3. MEET THE RIFLE DESIGNER4. BROWNING MODEL 1885 BPCR4.1 .40-65 & .45-70 BPC RIFLES4.2 .45-90 CREEDMOOR-TYPE LONG RANGE RIFLE5. RECEIVER & ACTION5.1 OVERALL ACTION5.2 TRIGGER DESIGN5.3 EXTRACTOR DESIGN5.4 .40-65 EXTRACTION ISSUE5.5 CASE RIM EDGE VISIBLE WITH ACTION CLOSED6. BARRELS6.1 MUZZLE CROWNS6.2 CHAMBERS6.3 CONCENTRIC CHAMBER CONCERNS7. SIGHTS7.1 FRONT SIGHT INSERTS8. STOCK, GRIP CAP, BUTT PLATE & FOREARM9. ADDITIONAL RIFLE DATA10. BROWNING/WINCHESTER PRODUCTION HISTORY10.1 BROWNING PRODUCTION10.2 WINCHESTER PRODUCTION11. BROWNING/WINCHESTER SERIAL NUMBERS11.1 BROWNING SERIAL NUMBERS11.2 WINCHESTER SERIAL NUMBERS12. MIROKU FIREARMS MANUFACTURING COMPANY13. RIFLE BOXES, SIGHT BOXES & LABELS13.1 RIFLE BOXES13.2 RIFLE BOX END LABELS13.3 REAR SIGHT BOXES & LABELS14. SALES LITERATURE15. COLLECTING THE RIFLESAPPENDICESAPPENDIX 1 – OPERATIONS, SPECIFICATIONS & GUNSMITHING1A. CHAMBER & BORE DATA1A.1 CHAMBER TERMINOLOGY1A.2 BROWNING/WINCHESTER CHAMBERS1B. OPERATION OF THE ACTION1B.1 FIRING CONTROL & COCKING SEQUENCE1B.2 EXTRACTOR OPERATION SEQUENCE1C. ACTION DISASSEMBLY & ASSEMBLY1C.1 DISASSEMBLY1C.2 ASSEMBLY1D. REAR SIGHT ISSUES1D.1 EXCESSIVE FORE & AFT MOVEMENT1D.2 EXCESSIVE LATERAL MOVEMENT1D.3 LADDER DETENT RELIABILITY1D.4 ENLARGING EYECUP HOLE DIAMETERS1D.5 WINDAGE ADJUSTMENT TENSION1E. FRONT SIGHT ISSUES1E.1 REPLACING SPIRIT LEVEL TUBE CAPS1E.2 REPLACING THE SPIRIT LEVEL VIAL1E.3 REFILLING THE SPIRIT LEVEL VIAL1E.4 LOOSE CREEDMOOR SIGHT1F. TRIGGER ISSUES1F.1 TRIGGER PULL ADJUSTMENT ISSUES1F.2 QUICK & CHEAP WAY TO LIGHTEN TRIGGER PULL1F.3 DALE MCGEE MODIFICATION1F.4 J&B INNOVATIONS TRIGGER KIT1F.5 LEE SHAVER’S TRIGGER SEAR1G. REINFORCING THE STOCK THROUGH-BOLT HOLE1H. ADDITIONAL GUNSMITHING NOTES1H.1 HAMMER WILL NOT COCK – RESTS ON THE FIRING PIN1H.2 HAMMER WILL NOT GO TO FULL COCK1H.3 HAMMER STOPS AT HALF-COCK WHEN FIRED1H.4 LIGHT (WEAK) PRIMER STRIKE1H.5 EXTRACTOR BLOCKS CARTRIDGE RIM1H.6 FIXING .40-65 EXTRACTION PROBLEM1H.7 ACTION LOCKS UP OR EXTRACTOR DOES NOT WORK1H.8 COMMENTS ON STOCK REPLACEMENT1H.9 COMMENTS ON BARREL REPLACEMENT1H.10 REMOVING A TIGHT FOREARM1H.11 FOREARM MODIFICATIONS TO IMPROVE ACCURACY1I. RIFLE 1ST AID KIT1J. ACCESSORIES & PART SUPPLIERS1J.1 SOURCES FOR MODERN SCOPE BASES & RINGS1J.2 INSTALLING A WM MALCOLM-STYLE SCOPE1K. EXPLODED ILLUSTRATIONS & PARTS LISTAPPENDIX 2 – SHOOTING & CLEANING2A. BARREL BREAK-IN2A.1 BADGER BARREL’S BREAK-IN PROCEDURE2A.2 LEE SHAVER’S BREAK-IN PROCEDURE2B. SMOKELESS AMMUNITION2C. MOA SIGHT ADJUSTMENTS2C.1 REAR SIGHT WINDAGE2C.2 REAR SIGHT ELEVATION2C.3 CREEDMOOR FRONT SIGHT WINDAGE2D. SIGHT SETTINGS – MOAs vs. POINTS2E. SHOOTING SHORT-CASE CARTRIDGES – MYTHS & FACTS2F. CASE STRETCHING & SEPARATING2G. FOULING CONTROL2H. MAKING A BLOW TUBE2I. CLEANING THE ACTION & BREECHAPPENDIX 3 – RELOADING3A. CHAMBER CASTS & IMPACT IMPRESSIONS3A.1 SULFUR CHAMBER CASTS3A.2 CERROSAFE CHAMBER CASTS3A.3 ADJUSTING DATA TAKEN FROM “AGED” CASTS3A.4 IMPACT IMPRESSIONS3B. “GREASE-GROOVE” BULLET MOULD CONSIDERATIONS3B.1 SELECTING A MOULD MANUFACTURER3B.2 SELECTING AND/OR SPECIFYING A MOULD3C. BULLET CASTING & LUBRICATION3C.1 DIP (LADLE) BULLET CASTING3C.2 BULLET LUBRICATION3D. DETERMINING OVERALL CASE LENGTH3D.1 QUICK METHODS3D.2 UTILIZING A CHAMBER CAST OR IMPACT IMPRESSION3E. ANNEALING CASE NECKS3F. STRETCHING SHORT BRASS3F.1 CASE STRETCHING OPTIONS3G. TO RESIZE OR NOT TO RESIZE?3H. LARGE PISTOL PRIMERS & PRIMER WADS3H.1 LARGE PISTOL PRIMERS3H.2 PRIMER WADS3I. MAKING .40-65 FROM .45-70 BRASS3I.1 A REFORMING TECHNIQUE3I.2 FIRE REFORMING ALTERNATIVE3I.3 MY PREFERRED REFORMING METHOD3J. CASE PREPARATION & LOADING3J.1 NEW CASE PREPARATIONS3J.2 LOADING STEPS3K. BROWNING/WINCHESTER LOAD SPECIFICATIONS3K.1 .40-65 WINCHESTER3K.2 .45-70 GOVERNMENT3K.3 .45-90 WINCHESTER3L. CASE CLEANING – TUMBLER vs. ULTRASONIC3L.1 ULTRASONIC VERSUS TUMBLER WITH CERAMIC MEDIA3L.2 TUMBLER WITH STAINLESS STEEL PINSAPPENDIX 4 – GENERAL INFORMATION4A. SHIPPING RIFLES & CRACKED STOCKS4B. CASE HARDENING & CASE COLORS4B.1 PROTECTING CASE COLORS4C. THE STORY OF CREEDMOOR4C.1 THE STORY OF CREEDMOOR4C.2 ADDITIONAL CREEDMOOR INFORMATION4D. REFERENCES

Price: 57.95 USD

Location: Pflugerville, Texas

End Time: 2024-08-29T01:57:34.000Z

Shipping Cost: 5.38 USD

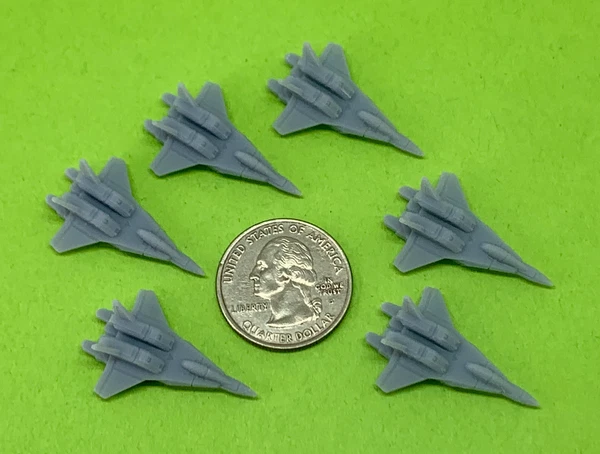

Product Images

Item Specifics

All returns accepted: ReturnsNotAccepted

Brand: Unbranded